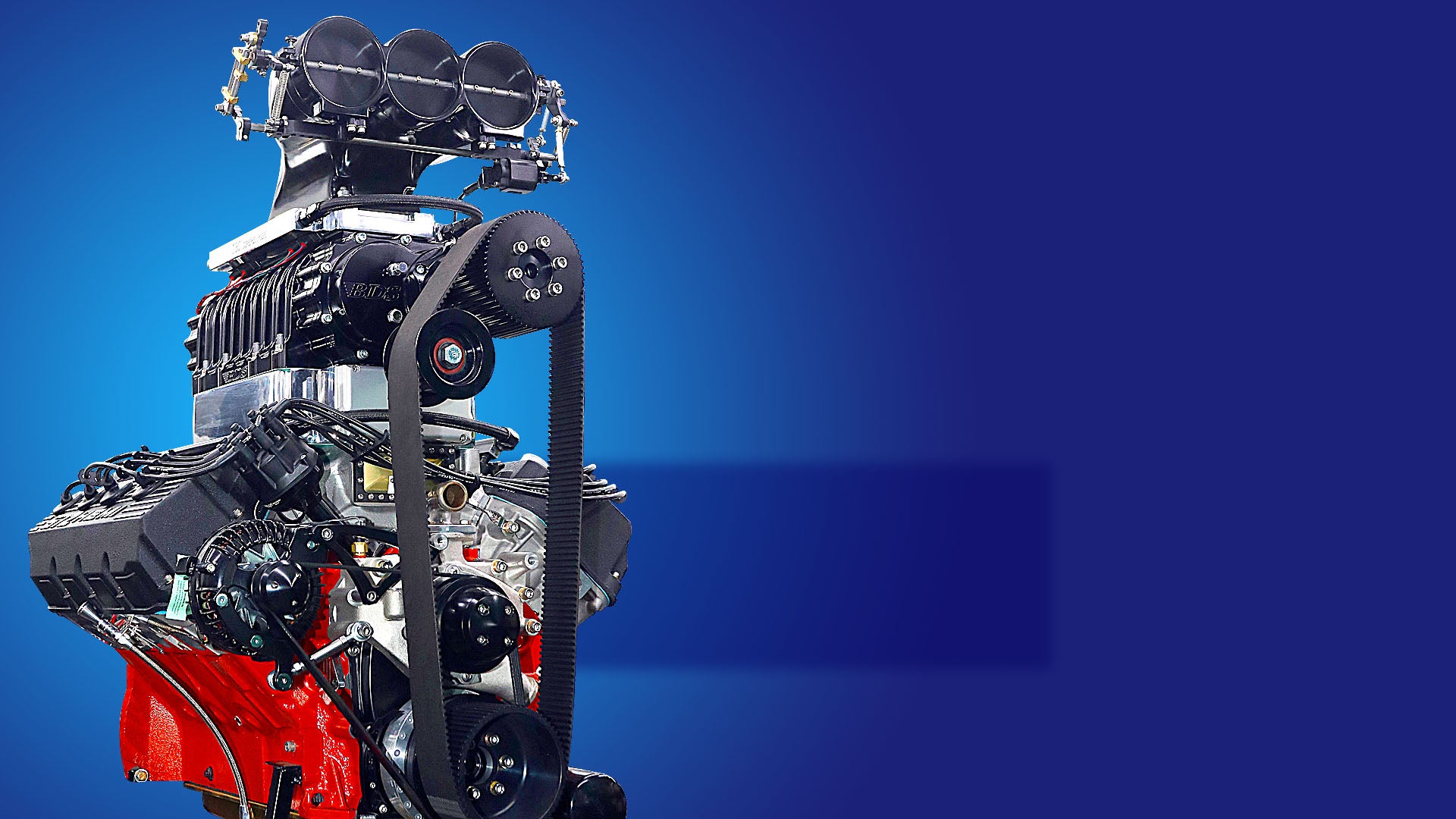

The Horsepower Monster

Crossed Pistons Black T-Shirt

Regular price

$27.99 USD

Regular price

Sale price

$27.99 USD

Unit price

per

Shipping calculated at checkout.

Share

Featured products

-

(NEW!) Crossed Pistons T Shirt in Heather Gray

Regular price From $27.99 USDRegular priceUnit price per -

Crossed Pistons Black T-Shirt

Regular price From $27.99 USDRegular priceUnit price per -

Crossed Pistons Decal

Regular price $4.99 USDRegular priceUnit price per -

Crossed Pistons Gray T-Shirt

Regular price From $27.99 USDRegular priceUnit price per -

Horsepower Monster Decal

Regular price $3.99 USDRegular priceUnit price per